For other hydraulic test benches, please click on the left!

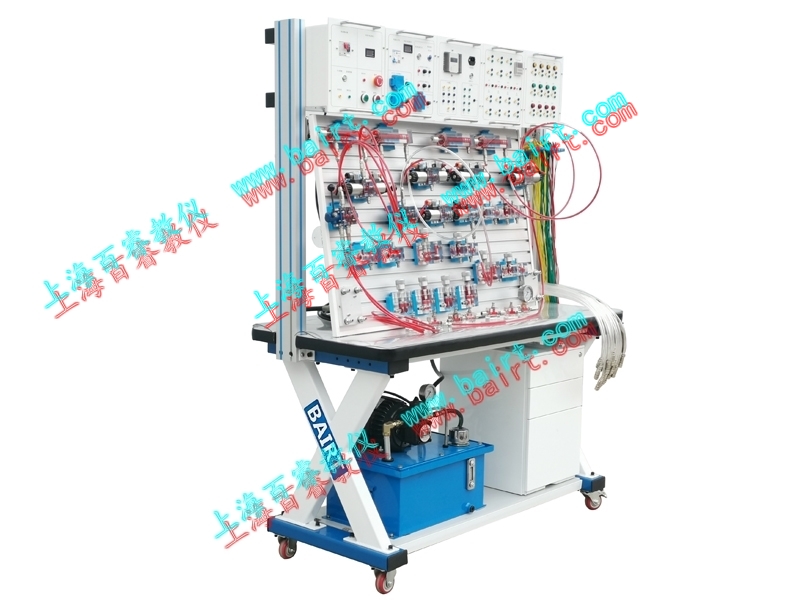

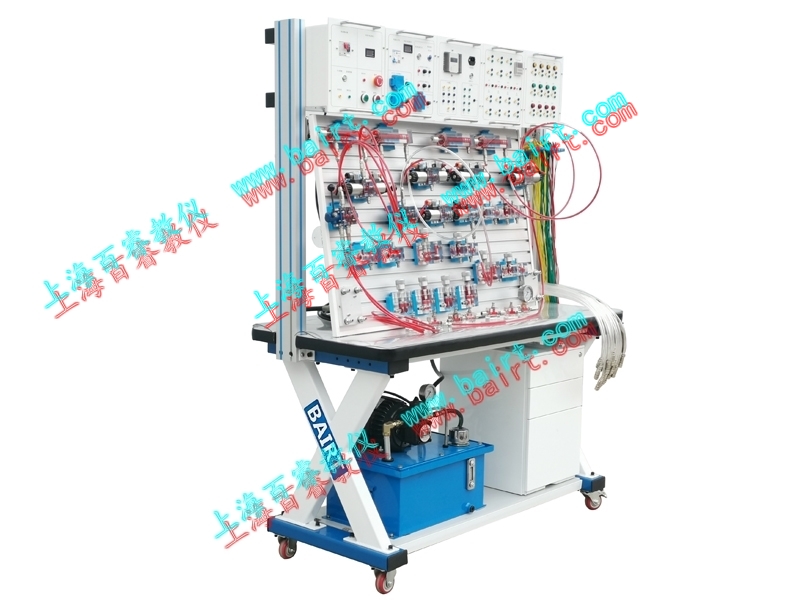

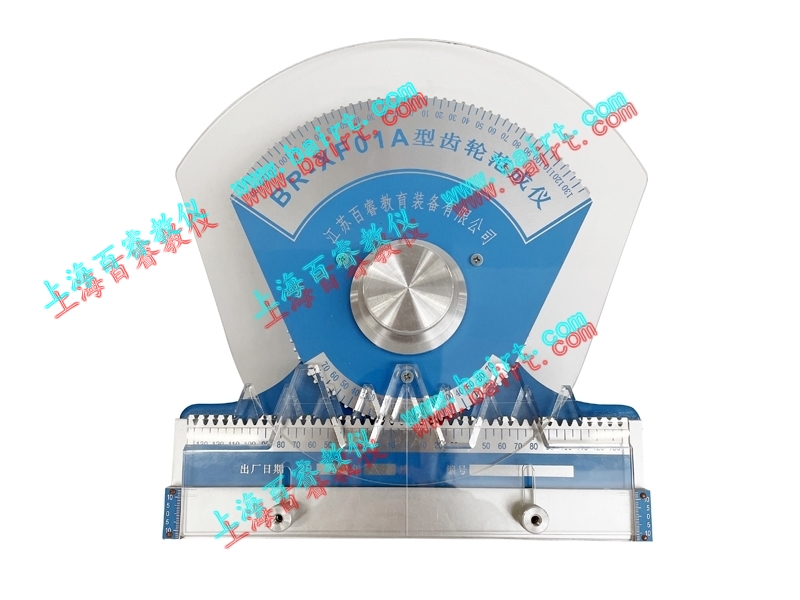

TY-A transparent hydraulic transmission experimental platform

Fashionable profile design

Regular sheet metal models

1�����、 Product Introduction

In order to adapt to the development of various fields as soon as possible, cultivate a large number of technical workers, technicians, engineers who master the basic knowledge and practical operation skills of hydraulic transmission, and transport them to various fronts of socialist construction. Based on the requirements of textbooks such as Hydraulic Transmission, Hydraulic Principles, and Mechanical Foundations, as well as the characteristics of hydraulic components in China, and with reference to advanced foreign technologies, our company has made efforts to explore for many years. Based on theory and through experiments, we have adopted high-precision processing technology to overcome the thermoplastic nature of transparent organic plastics, which are prone to deformation, poor mechanical strength, and surface smoothness of hydraulic components, A series of practical difficulties with high structural accuracy requirements led to the successful development of the TY-A transparent hydraulic transmission experimental platform.

The requirements of various machinery for hydraulic transmission are diverse, generally composed of basic functional circuits such as direction control circuit, pressure control circuit, speed control circuit, sequence control circuit, etc. The main frame of the experimental platform is refined from 1.0mm cold-rolled steel plate, with a painted surface that is aesthetically pleasing and sturdy. The bottom is equipped with four high-quality axial universal wheels, making it easy to move. The bottom of the cabinet is divided into two parts. The left side is used to place the hydraulic pump station, and the right side is a storage cabinet used to store transparent hydraulic components.

Each hydraulic component adopts a spring-loaded transition bottom plate, which has a beautiful and generous overall appearance, a sturdy and durable structure, and convenient operation. This demonstration system enables students to familiarize themselves with the structures, performance, and applications of over 20 commonly used hydraulic components, master the working processes and principles of more than ten basic circuits, and improve their ability to handle faults and solve problems through experimental demonstrations of 18 basic control circuits with the above four basic functions (up to 60 extended experiments). Through these demonstrations, students are inspired and interested, It can be used to conduct extended experiments on other oil circuits within the tolerance range of various components provided by this product (such as oil circuit design and graduation design).

This hydraulic test bench product references the characteristics of domestic hydraulic components, making it more suitable for teaching requirements in China. The system adopts transparent hydraulic components, a combination card slot structure, movable oil circuit joints, and general electrical circuits. By using attached tool materials and referring to experimental manuals, various commonly used hydraulic transmission control experiments can be conveniently carried out, allowing students to understand the principles, structures, and working processes of oil circuits and hydraulic components. It is an ideal equipment for hydraulic transmission teaching.

2���、 Main technical indicators

1. Working power supply:

220V 50Hz (mains) two-phase to 220V ± 10%

Rated power of the system: ≤ 1KW Rated pressure: 0-1.0 Mpa

2. Experimental bench

External dimensions: 1500mm (length) × 650mm (width) × 1800mm high.

Its packaging weight is about 150kg

3. PLC programmable controller:

Programmable Logic Controller (PLC): standard with German Siemens S7-200 SMART SR20, 20 I/O ports, relay output form;

The electrical control adopts a DC 24V power supply, solenoid valve output control port, proximity switch, connecting cables, sockets, buttons, indicator lights, etc.

The standard brand is recommended by our company, and customers can choose according to their own needs. Considering the impact of price, we will further communicate and adjust your selection.

4. Hydraulic experimental pump station

Working power supply: AC: 220V motor power 750W, motor speed: 0-1450 rpm

The pump is a low-pressure gear pump, model CB-B2.5, with a rated displacement of 2.5ml/rpm.

Fuel tank: nominal volume 40L; Equipped with liquid level and oil temperature indicators, oil suction filters, air filters, etc.

5. Demonstration experiment

The required pressure for oil circuit fluid flow is only 0.3-0.5Mpa (maximum pressure for oil pump: Pmax=1.2Mpa)

3、 Main features:

1. The valve body is made of transparent organic glass material, and the internal structure and workflow of the hydraulic transmission device can be observed clearly.

2. The leak proof quick insertion interface makes the assembly of the experimental circuit simple, fast, clean, and clean. Each hydraulic component is equipped with a mounting plate, which allows for easy and flexible placement of hydraulic components on aluminum alloy profile panels. The oil circuit overlap adopts an open and closed self-locking quick change joint, which is easy to disassemble and does not leak oil.

3. Independent component modules with convenient installation methods (aluminum alloy profile structure with "T" groove on the operation panel) can be freely combined with various experimental modules to build various experimental circuits.

The maximum withstand pressure of hydraulic components is 1.2Mpa, and the rated working pressure is 0.8Mpa, making it a safe low-pressure experimental system.

5. Adopting programmable logic controller (PLC) control to optimize the control scheme

6. Add configuration simulation software to enhance functionality.

7. Add hydraulic simulation software, virtual software circuit overlap and fault detection functions.

4�、 Experimental bench function:

1. Hydraulic transmission basic circuit experiment;

1) Sequential action circuit of proximity switch control

2) Two stage speed control circuit

3) The reversing circuit of a three position five way manual reversing valve

4) Multi stage voltage regulation circuit

5) Throttle valve oil inlet throttle speed control circuit

6) Speed control valve return oil throttle speed control circuit

7) Two stage voltage regulation circuit

8) The pressure reducing circuit of the pressure reducing valve

9) Speed switching circuit of speed control valve series connection

10) Speed switching circuit for parallel connection of speed control valves

11) Unloading circuit of three-way four-way solenoid valve (M-type)

12) Unloading circuit of pilot operated relief valve

13) The sequential action circuit of sequential valve control

14) Sequential action circuit controlled by pressure relay

15) Balance circuit of sequence valve

2. Programmable Logic Controller (PLC) electrical control experiment, in the form of mechatronic and hydraulic integrated control experiment.

1) Learning instruction programming for PLC and ladder diagram programming

2) Learning and using PLC programming software

3) Communication between PLC and computer, online debugging and monitoring

4) Optimization of hydraulic transmission control by PLC

3. Equipped with excavator simulation mechanism (optional part) (provide on-site operation video of hydraulic excavator simulation mechanism)

1) Observation, disassembly and assembly of various components in hydraulic transmission, and learning and analysis of hydraulic control system principles.

2) Hydraulic excavator demonstration control experiment.

① Excavation operations, bucket and stick composite work experiments;

② The position and height of the boom can be adjusted simultaneously for unloading operations, bucket operation, and bucket operation.

4. Equipped with a loader simulation mechanism (optional) (provide on-site operation video of the hydraulic loader simulation mechanism)

1) Observation, disassembly and assembly of various components in hydraulic transmission, and learning and analysis of hydraulic control system principles.

2) Hydraulic loading machinery demonstration control experiment.

① Loading operation, after the bucket is loaded, the rocker arm cylinder extends to reverse the bucket and lift the boom;

② Unloading operation, bucket unloading (rocker arm retracted, causing bucket to turn), boom lowering.

There are also various engineering machinery simulation mechanisms available for customers to choose from, including hydraulic loader simulation mechanisms, small hydraulic forklift simulation mechanisms, and small hydraulic crane simulation mechanisms. Welcome to inquire by phone.

Jiangsu Bairui Education Equipment Co., Ltd. is a production, research and development sales base established and constructed by Shanghai Bairui Education Equipment Group in Suqian City, Jiangsu Province in December 2016. According to the group's requirements, it aims for practical training and is a technology-based enterprise that integrates professional research and development, manufacturing, and sales. Dedicated to the production and sales of specialized products in the fields of intelligent flexible automation, robot cooperation, hydraulic and pneumatic, mold design and manufacturing, mechanical innovation design, and mechanical processing manufacturing in the mechanical majors of undergraduate, vocational, and technician colleges in higher education institutions. Bairui Education Instrument, an enterprise that has obtained national high-tech certification, is located in the dynamic Yangtze River Delta, relying on the Shanghai R&D center. Its production and sales factory is located in Suqian City, Jiangsu Province. It has favorable conditions such as a good investment and financing environment, strong scientific research capabilities, advanced manufacturing technology, strong manufacturing capabilities, convenient transportation, and beautiful ecology. The company covers an area of over 30000 square meters in production and office, with advanced complete processing equipment and complete product testing processes. The company has set up R&D Technology Department, Marketing Department, Work Safety Department, Finance Department, Logistics Supply Department and science and technology research team. The humanized management system is perfect, the supervision mechanism is perfect, and the ISO9001:2015 international quality management system has been operating in a standardized and strict manner for many years. The company has passed the OHSAS18001:2007 occupational health and safety management system certification, ISO14001:2015 environmental management system certification, and passed the GB/T29490-2013 intellectual property management system certification in 2020. It has been rated as: excellent supplier of government procurement, China's independent innovation brand, China's key recommended enterprise in the teaching equipment industry, excellent enterprise in the teaching equipment industry in China, national energy-saving and environmental protection products, and exemplary organization of after-sales service in the education equipment industry for many consecutive years; Obtained AAA level demonstration unit for honest operation, AAA level contract abiding and trustworthy enterprise, AAA level credit rating enterprise, AAA level credit enterprise, National 315 Integrity Enterprise, Top 100 Enterprises in the Industry, National Quality Trustworthy Product, and National Authoritative Testing Quality Qualified Product Certificate. The research team of Jiangsu Bairui Education Instrument has been committed to product improvement and innovation for a long time. They have developed nine series of nearly a hundred stable and advanced science and engineering teaching and training experimental equipment, making our company's basic practical and innovative technology products have a clear advantage in peer competition!

Return to homepage

Return to homepage Immediately call for consultation

Immediately call for consultation About Us

About Us Immediately consult online

Immediately consult online