QD-X type high standard innovative pneumatic training system

Overview:

This experimental platform is designed based on general textbooks such as "Hydraulic Pneumatic Transmission Technology and Training" and "Pneumatic Control Technology". It adopts a programmable logic controller (PLC), industrial pneumatic components, and execution modules as a whole. In addition to conducting conventional pneumatic basic control circuit experiments, it can also carry out pneumatic electrical control circuit application experiments, pneumatic PLC control circuit and other pneumatic technology course designs.

1、 Main features:

1. Component modularization: Each pneumatic component forms an independent module, equipped with a convenient installation base plate, which allows for the formation of various experimental circuits on universal aluminum alloy profiles. The operation is simple and fast.

2. Connection method: The connector adopts a fast type, which is reliable, simple, and time-saving during installation and disassembly.

3. Pneumatic components: Standard industrial pneumatic components with reliable and safe performance.

4. System environment: Low noise working pump station, providing a quiet experimental environment (noise<60).

2����、 Possible practical training projects (depending on the specific terminal execution structure)

1. Overlapping and experimentation of the basic pneumatic circuit;

Students can build experimental circuits and conduct related experiments based on the circuit schematic.

2. Practical training on the installation and debugging of simulation mechanisms for pneumatic loaders;

3. Practical training on the installation and debugging of simulation mechanisms for pneumatic excavators;

4. Practical training on the installation and debugging of simulation institutions for small logistics handling stations;

5. Training on the installation and debugging of modular flexible automation production training system;

6. Practical training on sensor application technology

The sensors involved in the device include capacitive, inductive, photoelectric, and electromagnetic, each with its own characteristics and playing a different role, enabling the system to work reliably. Students can enhance their intuitive understanding of various sensors in their work by understanding their working characteristics, which can enable them to quickly grasp the knowledge they have learned.

7. Pneumatic Application Technology Training

The pneumatic components involved in the device include: electrically controlled pneumatic valves, various pneumatic cylinders, pneumatic grippers, vacuum suction cups, vacuum generators, filtering deceleration valves, etc. When learning these pneumatic components, not only can each type of separation component be learned separately, but it is also possible to understand how various pneumatic components work together and coordinate with other components during learning.

8. PLC programming training

On this device, students can not only learn various technologies of PLC, but also learn various applications of PLC in a comprehensive technological environment. Provided conditions for flexible learning and mastery of various aspects of PLC knowledge.

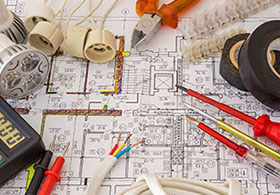

9. Electrical Control Circuit Training

The electronic control part of the device is designed in accordance with industrial standards and customs, and design drawings and instructions are provided. Students can learn circuit schematic analysis, PLC I/O address matching, and device circuit wiring methods on this device.

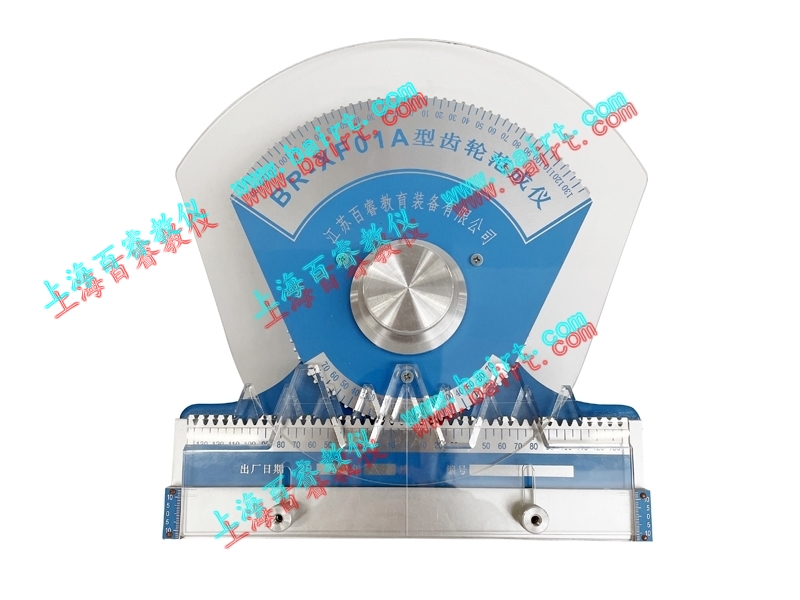

10. Mechanical System Debugging Training

When conducting online debugging, students need to adjust the coordination relationship between units until the system can run normally and reliably. This is of great help in improving the hands-on ability of students in school.

11. Practical training on system maintenance and fault detection technology

The content and methods of daily equipment maintenance, as well as methods for analyzing and troubleshooting common system faults.

Pneumatic basic circuit experimental project:

① PLC control circuit experiment:

1. Interlocking circuit

2. Buffer circuit

3. Primary pressure control circuit

4. Secondary pressure control circuit

5. Speed switching circuit

6. Dual acting cylinder bidirectional speed control circuit (outlet and inlet regulation)

7. High and low voltage switching circuit

8. Reversing circuit of double acting cylinder

9. Reversing circuit of single acting cylinder

10. Overload protection circuit

11. Time controlled single reciprocating circuit

12. Pressure controlled single reciprocating circuit

13. Position controlled single reciprocating circuit

14. Continuous reciprocating action circuit of single and double acting cylinders

15. Synchronous circuit using throttle valve

16. Three cylinder linkage circuit

17. Counting circuit

18. Delay circuit

19. Application circuit of OR logic (OR AND logic)

20. Two handed operation circuit

② Programmable Logic Controller (PLC) Electrical Control Experiment, Mechatronics Electric Gas Integrated Control Experiment:

⑴ Learning PLC basic instruction programming, special instruction programming, and ladder diagram programming

⑵ Learning and using PLC programming software

⑶ Communication and online debugging between PLC and computer

Control experiment combining PLC and pneumatic

③ Students can design, assemble, and expand various circuit experiments on their own, reaching over 130 types

④ Scalability Innovation Experiment

This experimental platform uses internationally advanced Japanese SMC pneumatic valves, a highly configured Omron 60 point programmable controller, and internationally leading FESTO simulation software, forming the most first-class experimental platform in China. We did not make the equipment a fixed and unchanging validation experimental platform, but provided a fully equipped, safe and open innovative operating platform. Under the guidance of our guidance, we truly achieved the transformation from validation experiments to innovative experiments, and from passive experiments to active experiments.

In order to meet the requirements of experimental teaching reform in schools, reducing confirmatory experiments, increasing design, comprehensive, and exploratory experiments, and developing students' independent innovative thinking. In addition to completing basic experiments on air pressure, it should also be combined with mechanical experimental projects to achieve the effect of a multifunctional machine; For example:

Excavator simulation mechanism;

Rotary feeding mechanism,

360 degree rotary robotic arm

Automation of small logistics transportation lines;

Combined with German Festo software, it can simulate various mechanical applications

3、 Composition of the experimental platform:

The experimental platform consists of several parts, including the experimental platform, working pump station, pneumatic components, electrical control unit, auxiliary components, etc.

1. Experimental bench: The experimental bench is composed of an iron main body (steel plate with a thickness of 1.0mm or more) made by a one-time forming process, an aluminum alloy operation panel, etc., and is equipped with a leak proof oil return groove, which is practical and clever. The entire bench undergoes rust and oil removal, sanding, and spraying processes, followed by rust prevention, dust prevention, and anti-static treatment, ensuring safety and reliability.

Workbench

Main size: Long × wide × Height=1500mm × 650mm × 1700mm (gross weight approximately 250kg)

Attached size: Long × wide × Height=1000mm × 650mm × 800mm (gross weight approximately 150kg)

2. Working pump station:

Air pump input voltage: AC 220V/50Hz

Motor (dual head) power: 250W

Rated output pressure: 0.8Mpa

Air pump volume: 20L

Working noise:<60 decibels

3. Pneumatic components:

Mainly imported SMC pneumatic components from Japan, with detailed configuration in the attachment.

The pneumatic components are all equipped with a sky blue transition base plate (synthetic ABS), which can be conveniently and freely placed on the experimental panel (aluminum alloy profile structure with "T" grooves on the panel). The circuit overlap adopts quick change joints, which are convenient and fast for disassembly and connection, and low voltage is safe and reliable.

4. Electrical control unit:

Programmable Logic Controller (PLC); Adopting the Japanese Omron brand, with 60 I/O ports; Relay output form.

Power supply voltage: AC 220V/50Hz

5. Equipped with a set of German FESTO aerodynamic simulation software.

Jiangsu Bairui Education Equipment Co., Ltd. is a production, research and development sales base established and constructed by Shanghai Bairui Education Equipment Group in Suqian City, Jiangsu Province in December 2016. According to the group's requirements, it aims for practical training and is a technology-based enterprise that integrates professional research and development, manufacturing, and sales. Dedicated to the production and sales of specialized products in the fields of intelligent flexible automation, robot cooperation, hydraulic and pneumatic, mold design and manufacturing, mechanical innovation design, and mechanical processing manufacturing in the mechanical majors of undergraduate, vocational, and technician colleges in higher education institutions. Bairui Education Instrument, an enterprise that has obtained national high-tech certification, is located in the dynamic Yangtze River Delta, relying on the Shanghai R&D center. Its production and sales factory is located in Suqian City, Jiangsu Province. It has favorable conditions such as a good investment and financing environment, strong scientific research capabilities, advanced manufacturing technology, strong manufacturing capabilities, convenient transportation, and beautiful ecology. The company covers an area of over 30000 square meters in production and office, with advanced complete processing equipment and complete product testing processes. The company has set up R&D Technology Department, Marketing Department, Work Safety Department, Finance Department, Logistics Supply Department and science and technology research team. The humanized management system is perfect, the supervision mechanism is perfect, and the ISO9001:2015 international quality management system has been operating in a standardized and strict manner for many years. The company has passed the OHSAS18001:2007 occupational health and safety management system certification, ISO14001:2015 environmental management system certification, and passed the GB/T29490-2013 intellectual property management system certification in 2020. It has been rated as: excellent supplier of government procurement, China's independent innovation brand, China's key recommended enterprise in the teaching equipment industry, excellent enterprise in the teaching equipment industry in China, national energy-saving and environmental protection products, and exemplary organization of after-sales service in the education equipment industry for many consecutive years; Obtained AAA level demonstration unit for honest operation, AAA level contract abiding and trustworthy enterprise, AAA level credit rating enterprise, AAA level credit enterprise, National 315 Integrity Enterprise, Top 100 Enterprises in the Industry, National Quality Trustworthy Product, and National Authoritative Testing Quality Qualified Product Certificate. The research team of Jiangsu Bairui Education Instrument has been committed to product improvement and innovation for a long time. They have developed nine series of nearly a hundred stable and advanced science and engineering teaching and training experimental equipment, making our company's basic practical and innovative technology products have a clear advantage in peer competition!

Return to homepage

Return to homepage Immediately call for consultation

Immediately call for consultation About Us

About Us Immediately consult online

Immediately consult online