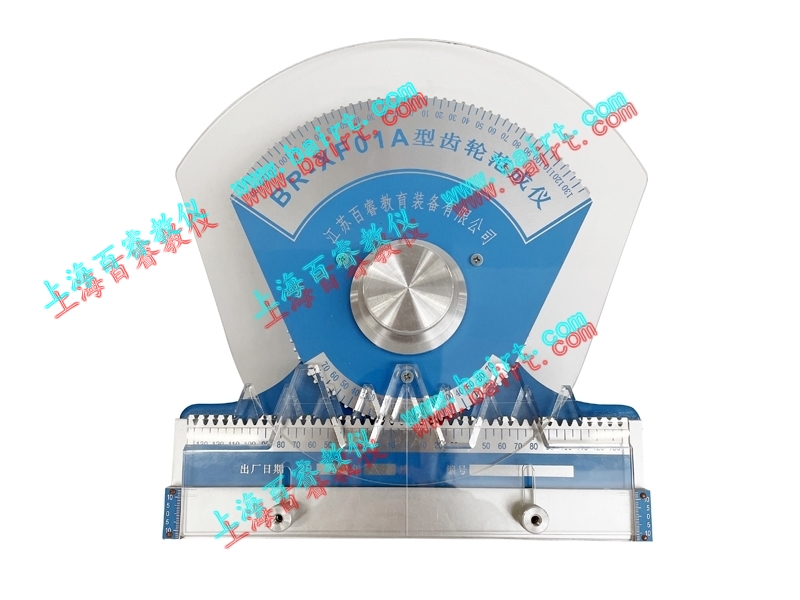

Jiangsu Bairui Education Equipment Co., Ltd. is a production, research and development sales base established and constructed by Shanghai Bairui Education Equipment Group in Suqian City, Jiangsu Province in December 2016. According to the group's requirements, it aims for practical training and is a technology-based enterprise that integrates professional research and development, manufacturing, and sales. Dedicated to the production and sales of specialized products in the fields of intelligent flexible automation, robot cooperation, hydraulic and pneumatic, mold design and manufacturing, mechanical innovation design, and mechanical processing manufacturing in the mechanical majors of undergraduate, vocational, and technician colleges in higher education institutions. Bairui Education Instrument, an enterprise that has obtained national high-tech certification, is located in the dynamic Yangtze River Delta, relying on the Shanghai R&D center. Its production and sales factory is located in Suqian City, Jiangsu Province. It has favorable conditions such as a good investment and financing environment, strong scientific research capabilities, advanced manufacturing technology, strong manufacturing capabilities, convenient transportation, and beautiful ecology. The company covers an area of over 30000 square meters in production and office, with advanced complete processing equipment and complete product testing processes. The company has set up R&D Technology Department, Marketing Department, Work Safety Department, Finance Department, Logistics Supply Department and science and technology research team. The humanized management system is perfect, the supervision mechanism is perfect, and the ISO9001:2015 international quality management system has been operating in a standardized and strict manner for many years. The company has passed the OHSAS18001:2007 occupational health and safety management system certification, ISO14001:2015 environmental management system certification, and passed the GB/T29490-2013 intellectual property management system certification in 2020. It has been rated as: excellent supplier of government procurement, China's independent innovation brand, China's key recommended enterprise in the teaching equipment industry, excellent enterprise in the teaching equipment industry in China, national energy-saving and environmental protection products, and exemplary organization of after-sales service in the education equipment industry for many consecutive years; Obtained AAA level demonstration unit for honest operation, AAA level contract abiding and trustworthy enterprise, AAA level credit rating enterprise, AAA level credit enterprise, National 315 Integrity Enterprise, Top 100 Enterprises in the Industry, National Quality Trustworthy Product, and National Authoritative Testing Quality Qualified Product Certificate. The research team of Jiangsu Bairui Education Instrument has been committed to product improvement and innovation for a long time. They have developed nine series of nearly a hundred stable and advanced science and engineering teaching and training experimental equipment, making our company's basic practical and innovative technology products have a clear advantage in peer competition!

Return to homepage

Return to homepage Immediately call for consultation

Immediately call for consultation About Us

About Us Immediately consult online

Immediately consult online