| Fixture basic components (24 types) |

| Number | name | specifications | Remarks |

| 1 | Five structural forms of typical basic components | 200×180×150 | All aluminum alloy material |

| 2 | Five structural forms of typical supporting components | 200×180×150 | All aluminum alloy material |

| 3 | Eight structural forms of typical positioning components | 200×180×150 | All aluminum alloy material |

| 4 | Five structural forms of typical guiding elements | 200×180×150 | All aluminum alloy material |

| 5 | Five structural forms of typical clamping components | 200×180×150 | All aluminum alloy material |

| 6 | Ten structural forms of typical composite components | 200×180×150 | All aluminum alloy material |

| 7 | Seven structural forms of typical parts | 200×180×150 | All aluminum alloy material |

| 8 | Single piece opposing two-point linkage mechanism | 140×140×120 | All aluminum alloy material |

| 9 | Eccentric shaft clamping mechanism | 180×150×130 | All aluminum alloy material |

| 10 | Double arm single action hinge clamping mechanism | 200×180×120 | All aluminum alloy material |

| 11 | Double arm double action hinge clamping mechanism | 200×160×120 | All aluminum alloy material |

| 12 | Structure of push type spring chuck | φ80×160 | All aluminum alloy material |

| 13 | Thin walled rubber tube light processing clamping fixture | 150×150×120 | All aluminum alloy material |

| 14 | External clamping device for hoop | φ100×160 | All aluminum alloy material |

| 15 | Spiral clamping structure with fine-tuning device | 200×100×120 | All aluminum alloy material |

| 16 | External swinging clamping device | 160×100×120 | All aluminum alloy material |

| 17 | Spiral clamping structure inside the box frame | 200×160×120 | All aluminum alloy material |

| 18 | Internal tensioning and clamping device | 150×150×160 | All aluminum alloy material |

| 19 | Elbow type clamping device | 180×100×120 | All aluminum alloy material |

| 20 | Structure of thrust clamping | 160×140×100 | All aluminum alloy material |

| 21 | Adjustable cam clamping device | 100×120×160 | All aluminum alloy material |

| 22 | Tiger clamp type clamping machine fixture | 200×140×120 | All aluminum alloy material |

| 23 | Pneumatic wedge clamping mechanism | 190×160×120 | All aluminum alloy material |

| 24 | The structure of the floating joint | φ60×160 | All aluminum alloy material |

| ★ 25 | Spring core shaft fixture |

| All aluminum alloy material |

| ★ 26 | Gap fit cylindrical core shaft fixture |

| All aluminum alloy material |

| Types of drilling machine fixtures (31 types) |

| Number | name | specifications | Remarks |

| ★ 27 | Downward pressure drilling die | φ160×160 | All aluminum alloy material |

| ★ 28 | Cover type drilling machine fixture | 280×110×80 | All aluminum alloy material |

| ★ 29 | Short axis drilling group drilling machine fixture | 200×160×100 | All aluminum alloy material |

| ★ 30 | Box drilling die | 140×110×120 | Provide structural diagrams and all aluminum alloy materials |

| 31 | Left and right bracket drilling fixtures | 200×150×120 | All aluminum alloy material |

| 32 | Double arm crank drilling combination fixture | 250×210×150 | Provide structural diagrams and all aluminum alloy materials |

| ★ 33 | Indexing drilling machine fixture | 200×145×150 | Provide structural diagrams and all aluminum alloy materials |

| ★ 34 | Fixed drilling jig | 190×120×150 | Provide structural diagrams and all aluminum alloy materials |

| ★ 35 | Rotary drilling die | 180×140×140 | Provide structural diagrams and all aluminum alloy materials |

| ★ 36 | Flipping drill die | 160×200×150 | Provide structural diagrams and all aluminum alloy materials |

| 37 | Manual sliding column drilling die | 180×190×210 | Provide structural diagrams and all aluminum alloy materials |

| 38 | Detachable drilling template | 260×120×110 | Provide structural diagrams and all aluminum alloy materials |

| 39 | Suspended drilling template | 220×170×140 | Provide structural diagrams and all aluminum alloy materials |

| ★ 40 | Drilling fixture with indexing device | 210×180×130 | Provide structural diagrams and all aluminum alloy materials |

| ★ 41 | Hinged drilling machine fixture | 250×90×130 | Provide structural diagrams and all aluminum alloy materials |

| 42 | Hanging drilling template drilling machine fixture | 230×160×160 | Provide structural diagrams and all aluminum alloy materials |

| 43 | Multi sided flipping drilling machine fixture | 140×140×170 | All aluminum alloy material |

| ★ 44 | Fork group drilling machine fixture | 200×130×190 | All aluminum alloy material |

| 45 | Pneumatic single sliding column drilling die | 120×160×140 | All aluminum alloy material |

| 46 | Rear clamping drilling machine fixture | 150×140×140 | All aluminum alloy material |

| 47 | Jack up clamping drilling machine fixture | 150×140×140 | All aluminum alloy material |

| 48 | Steel sleeve drilling die | φ100×120 | All aluminum alloy material |

| 49 | Bracket oblique hole indexing drilling die | 200×160×100 | Provide structural diagrams and all aluminum alloy materials |

| 50 | Diagonal drilling die for tractor brake lever shell | 200×140×140 | All aluminum alloy material |

| 51 | Universal rotary drilling machine fixture | 330×130×170 | Provide structural diagrams and all aluminum alloy materials |

| 52 | Swinging drilling machine fixture | 185×180×140 | Provide structural diagrams and all aluminum alloy materials |

| 53 | Diagonal drilling machine fixture | 160×150×160 | All aluminum alloy material |

| 54 | Drill mold for locking holes in the rocker arm | 200×120×120 | Provide structural diagrams and all aluminum alloy materials |

| 55 | Mobile drilling machine fixture | 150×100×150 | All aluminum alloy material |

| 56 | Drill die for the cover plate of the gear wheel | 140×60×120 | All aluminum alloy material |

| 57 | Spring compression drill pipe joint small hole drilling die | 200×80×120 | All aluminum alloy material |

| ★ 58 | Universal adjustable drilling machine fixture |

| All aluminum alloy material |

| Milling machine fixture category (32 types) |

| Number | name | specifications | Remarks |

| ★ 59 | Iron support foot milling machine fixture | 200×120×160 | Provide structural diagrams and all aluminum alloy materials |

| ★ 60 | Milling nose vertical milling machine fixture | 210×170×130 | Provide structural diagrams and all aluminum alloy materials |

| ★ 61 | Continuous clamping adjustable milling machine fixture | 180×120×150 | All aluminum alloy material |

| 62 | Milling Machine Fixture for Milling Tee Slots | 200×160×115 | Provide structural diagrams and all aluminum alloy materials |

| 63 | Multi piece linkage clamping milling machine fixture | 240×120×80 | All aluminum alloy material |

| 64 | Grinding tool machine fixture | 250×190×140 | All aluminum alloy material |

| 65 | Pneumatic clamping milling machine fixture | 255×200×170 | Provide structural diagrams and all aluminum alloy materials |

| 66 | Multipurpose milling machine fixture | 250×180×120 | Provide structural diagrams and all aluminum alloy materials |

| 67 | Model milling machine fixture | 200×170×190 | Provide structural diagrams and all aluminum alloy materials |

| ★ 68 | Eccentric clamping milling machine fixture | 230×140×180 | Provide structural diagrams and all aluminum alloy materials |

| 69 | Multi piece clamping and milling machine fixture | 200×140×180 | All aluminum alloy material |

| 70 | Positioning first and then clamping the milling machine fixture | 160×140×150 | All aluminum alloy material |

| 71 | Double circular axis milling keyway fixture | 180×120×120 | All aluminum alloy material |

| 72 | Circular workpiece milling machine fixture | 220×120×100 | All aluminum alloy material |

| 73 | Fixture for milling bearing shells | 160×150×120 | All aluminum alloy material |

| 74 | Cover plate flat milling machine fixture | 200×200×120 | All aluminum alloy material |

| 75 | Lathe square tool holder milling machine fixture | 180×200×140 | All aluminum alloy material |

| 76 | Fork keyway milling machine fixture | 160×120×140 | All aluminum alloy material |

| 77 | Liquid plastic multi piece linkage clamping milling machine fixture | 280×100×110 | Provide structural diagrams and all aluminum alloy materials |

| 78 | Fork group milling machine fixture | 200×200×180 | Provide structural diagrams and all aluminum alloy materials |

| ★ 79 | Jig for group milling machine with fork mouth | 210×170×210 | All aluminum alloy material |

| ★ 80 | Wedge linkage clamping milling machine fixture | 240×150×270 | Provide structural diagrams and all aluminum alloy materials |

| ★ 81 | Spiral centering clamping milling machine fixture | 260×180×120 | Provide structural diagrams and all aluminum alloy materials |

| 82 | Fixture for milling semi circular keyway milling machine | 250×150×120 | All aluminum alloy material |

| ★ 83 | Milling machine fixture with auxiliary support | 210×150×160 | Provide structural diagrams and all aluminum alloy materials |

| 84 | Multi piece linkage clamping milling machine fixture | 240×120×80 | All aluminum alloy material |

| 85 | Two point linkage clamping fixture | 200×120×120 | All aluminum alloy material |

| 86 | Cushion block right angle milling machine fixture | 200×160×140 | Provide structural diagrams and all aluminum alloy materials |

| 87 | One point two sided positioning milling machine fixture | 200×160×130 | All aluminum alloy material |

| 88 | Indexing milling machine fixture | 300×200×120 | All aluminum alloy material |

| 89 | Linkage clamping milling machine fixture | 270×120×140 | Provide structural diagrams and all aluminum alloy materials |

| 90 | Milling fixture for 45 degree milling machine | 280×150×150 | All aluminum alloy material |

| ★ 91 | Keyway milling machine fixture |

| All aluminum alloy material |

| ★ 92 | Fixture for Milling Fork Tooth Top Surface Milling Machine |

| All aluminum alloy material |

| Lathe fixture categories (38 types) |

| Number | name | specifications | Remarks |

| 93 | Four types of connections between lathe fixtures and machine tool spindles | 200×250×150 | All aluminum alloy material |

| 94 | Centrifugal force lathe fixture | φ160×280 | All aluminum alloy material |

| ★ 95 | Group lathe fixture | φ180×150 | All aluminum alloy material |

| ★ 96 | Angle iron lathe fixture | 160×120×180 | Provide structural diagrams and all aluminum alloy materials |

| 97 | Elastic roller centering clamping lathe fixture | φ120×160 | Provide structural diagrams and all aluminum alloy materials |

| 98 | Linkage spiral clamping lathe fixture | φ170×240 | All aluminum alloy material |

| 99 | Liquid plastic centering and clamping lathe fixture | φ180×210 | All aluminum alloy material |

| 100 | Pipe joint group lathe fixture | φ160×250 | All aluminum alloy material |

| 101 | Fork group lathe fixture | φ180×270 | Provide structural diagrams and all aluminum alloy materials |

| 102 | Group lathe fixtures for disc and sleeve parts | φ180×210 | Provide structural diagrams and all aluminum alloy materials |

| ★ 103 | Fork mouth group lathe fixture | φ180×80 | All aluminum alloy material |

| 104 | Hydraulic clamping lathe fixture | φ180×290 | All aluminum alloy material |

| ★ 105 | Lathe fixture with indexing device | φ180×140 | Provide structural diagrams and all aluminum alloy materials |

| 106 | Pump body hole lathe fixture | 190×150×120 | Provide structural diagrams and all aluminum alloy materials |

| 107 | Multi piece clamping lathe fixture | φ170×120 | All aluminum alloy material |

| ★ 108 | Circular spiral clamping lathe fixture | φ200×110 | All aluminum alloy material |

| 109 | Fully positioned lathe fixture | 160×160×180 | All aluminum alloy material |

| 110 | Special vehicle eccentric lathe fixture | φ160×160 | All aluminum alloy material |

| 111 | Turning combination fixture | φ180×170 | Provide structural diagrams and all aluminum alloy materials |

| 112 | Crankshaft neck lathe fixture | φ160×150 | All aluminum alloy material |

| 113 | Eccentric axis lathe fixture | φ120×180 | All aluminum alloy material |

| 114 | Self positioning lathe fixture | φ150×180 | All aluminum alloy material |

| 115 | Lathe square tool holder | 180×150×140 | All aluminum alloy material |

| 116 | CNC lathe automatic indexing hexagonal tool holder | 180×150×140 | All aluminum alloy material |

| 117 | Yu Xiang Hollow Sliding Block Lathe Fixture | φ140×120 | All aluminum alloy material |

| 118 | Lathe fixture for machining holes on opening and closing nuts | φ180×150 | All aluminum alloy material |

| 119 | Lathe fixture for switch contact seat | φ160×200 | All aluminum alloy material |

| 120 | Valve plate inclined lathe fixture | φ160×100 | All aluminum alloy material |

| 121 | Gate valve body rotary lathe fixture | φ160×120 | All aluminum alloy material |

| 122 | Fixture for indexing lathe with outer circular and square groove of cross shaft | φ160×120 | All aluminum alloy material |

| 123 | Hydraulic pull rod sleeve lathe fixture | φ160×200 | All aluminum alloy material |

| 124 | Right angle joint lathe fixture | φ160×200 | All aluminum alloy material |

| 125 | Valve body four hole eccentric rotary lathe fixture | φ180×140 | All aluminum alloy material |

| 126 | Adjustable lathe fixture | φ180×120 | All aluminum alloy material |

| 127 | Thin walled sleeve elastic lathe fixture | φ90×160 | All aluminum alloy material |

| 128 | Corrugated sleeve centering lathe fixture | φ100×160 | All aluminum alloy material |

| 129 | Shell lathe fixture | φ160×140 | All aluminum alloy material |

| 130 | Fixture for return water cover indexing lathe | 180×150×120 | All aluminum alloy material |

| Types of boring machine fixtures (4 types) |

| Number | name | specifications | Remarks |

| 131 | Box boring machine fixture (with boring cutter) | 220×150×120 | Provide structural diagrams and all aluminum alloy materials |

| 132 | Double support boring machine fixture (with boring cutter) | 250×190×140 | Provide structural diagrams and all aluminum alloy materials |

| 133 | Vertical boring machine fixture | 200×140×140 | All aluminum alloy material |

| 134 | Boring Machine Fixture for Boring Lathe Tailstock Holes | 220×160×130 | Provide structural diagrams and all aluminum alloy materials |

| ★ 135 | Fixture for precision boring of large and small holes in connecting rods |

| All aluminum alloy material |

| ★ 136 | Front and rear double support boring machine fixture |

| All aluminum alloy material |

| Welding fixture categories (3 types) |

| Number | name | specifications | Remarks |

| 137 | Box frame welding fixture | 260×150×160 | All aluminum alloy material |

| 138 | Welding fixture for shovel excavator bucket | 200×160×130 | All aluminum alloy material |

| 139 | Automotive welding fixture | 200×160×130 | All aluminum alloy material |

| Inspection fixture categories (6 types) |

| Number | name | specifications | Remarks |

| 140 | Fixture for checking part dimensions | 270×200×150 | All aluminum alloy material |

| 141 | Fixture for inspecting substrate R (with dial gauge) | 220×210×90 | All aluminum alloy material |

| 142 | Hole spacing inspection fixture (with dial gauge) | 210×120×70 | All aluminum alloy material |

| 143 | Fixture for checking coaxiality (with dial gauge) | 230×130×180 | Provide structural diagrams and all aluminum alloy materials |

| 144 | Check the parallelism of the dovetail guide rail fixture (with a dial gauge) | 150×250×150 | Provide structural diagrams and all aluminum alloy materials |

| 145 | Fixture for checking the verticality of holes and end faces | φ100×160 | All aluminum alloy material |

| 146 | Universal combination fixture for hole system | 290×160×210 | Provide structural diagrams and all aluminum alloy materials |

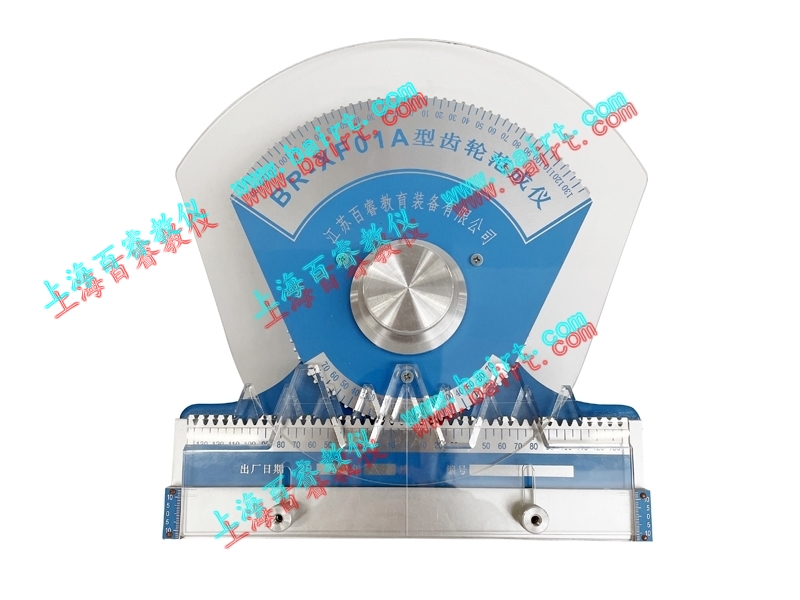

| 11 types of fixtures for combination, grinding, drawing, and gear processing |

| Number | name | specifications | Remarks |

| 147 | Universal combination fixture for slot system | 260×160×210 | All aluminum alloy material |

| 148 | Vacuum clamping grinding machine fixture | 200×120×80 | All aluminum alloy material |

| 149 | Guide rail grinder fixture | 200×160×120 | All aluminum alloy material |

| 150 | Adjustable fixture for grinding convex key shaft | 160×140×150 | All aluminum alloy material |

| 151 | Swallowtail groove planing fixture | 240×160×120 | All aluminum alloy material |

| 152 | Assembly fixture | 180×140×140 | All aluminum alloy material |

| 153 | Spline key hole group broaching machine fixture (including spline broach) | 200×180×150 | All aluminum alloy material |

| 154 | Gear hobbing fixture for Y38-1 gear hobbing machine tool | φ140×200 | All aluminum alloy material |

| 155 | Gear hobbing fixture for L300 gear hobbing machine tool | φ140×180 | All aluminum alloy material |

| 156 | External gear slotting fixture | φ120×160 | All aluminum alloy material |

| 157 | Internal gear slotting fixture | φ160×120 | All aluminum alloy material |

Return to homepage

Return to homepage Immediately call for consultation

Immediately call for consultation About Us

About Us Immediately consult online

Immediately consult online