| Number | name | Specification mm | Remarks |

| Five structural forms of typical basic components | Size: 200 × one hundred and eighty × 150

Base 150 × two hundred and ninety × 20

V-block 40 × forty × 30

Limit block 50 × fifty × 10

Pressing the fixing part 60 × one hundred × 20

Plane limit block 50 × one hundred and ten × 30

Step axis Φ fifty × 110 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Five structural forms of typical supporting components | Size: 200 × one hundred and eighty × 150

Overall size 150 × three hundred and sixty × 170

Base 150 × three hundred and sixty × 20

Pad 30 × one hundred × 10

Cylindrical cushion block Φ fifty × 80

Adjustable cushion block fixing component Φ eighty × 70

Adjustable cushion block Φ twenty × 95

Spherical cushion block Φ sixty × 100

Connecting screw Φ ten × 100 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Eight structural forms of typical positioning components | Size: 200 × one hundred and eighty × 150

Base 150 × three hundred and sixty × 20

Positioning block for cylindrical platform Φ seventy × 20

Bushing type positioning parts Φ sixty × 100

Flat positioning piece -50 × sixty × 10

End face positioning block 40 × fifty × 70

Flat positioning part II 40 × fifty × 20

Positioning pin Φ sixty × 90

Bushing parts Φ seventy × 50

Cushion block Φ sixty × 10

Cylindrical positioning block Φ forty × 10 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Five structural forms of typical guiding elements | Size: 200 × one hundred and eighty × 150

Base 215 × two hundred and seventy-five × 14

V-shaped guide element 50 × sixty × 100

Cylindrical guide element Φ eighty × 30

Guide components for shaft sleeves Φ fifty × 20

Bolt guide element Φ eighty × 10

Bevel guide element Φ eighty × 30

Boosting block Φ ten × 10

Mechanism bolt Φ thirty × 30 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Five structural forms of typical clamping components | Size: 200 × one hundred and eighty × 150

Base 147 × one hundred and ninety-seven × 17

Adjustable compression block 170 × thirty × 10

Adjustable compression block II 70 × thirty × 10

Thin plate clamping piece 20 × twenty × 50

Slanted edge clamping block 40 × ninety × 10

Rotating clamping block 130 × sixty × 50

Rotating clamping block two Φ ten × 30 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Ten structural forms of typical composite components | Size: 200 × one hundred and eighty × 150

Base 360 × one hundred and fifty × 20

Compression block 20 × seventy × 10

Right angle positioning block 40 × forty × 20

Adjustable pressure block 20 × seventy × 20

40 pressure blocks with notches × sixty × 20

Adjustable fixing block 20 × ninety × 30

Right angle V-block 40 × seventy × 40

Adjustable steering parts 70 × seventy × 10

Square limit block 50 × fifty × 20

Square step limit block 40 × forty × 30 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Seven structural forms of typical parts | Size: 200 × one hundred and eighty × 150 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Single piece opposing two-point linkage mechanism | Size: 140 × one hundred and forty × 120

Fixture motherboard 160 × ninety × 80

Workpiece cushion plate 10 × ten × 60

Compression guide rod Φ twenty × 70

Compression block 40 × twenty × 20

Compression connection block 130 × forty × 20 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Eccentric shaft clamping mechanism | Size: 180 × one hundred and fifty × 130

Fixture motherboard 180 × one hundred and thirty × 120

Tight connecting plate 140 × thirty × 10

Compression guide rod Φ ten × 80

Compression block 30 × twenty × 10

Workpiece cushion plate 10 × ten × 130

Eccentric wheel Φ forty × 30 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Double arm single action hinge clamping mechanism | Size: 200 × one hundred and eighty × 120

Overall size 190 × one hundred and fifty-five × 90

Fixture base plate 160 × one hundred and twenty × 10

Hinge seat 30 × thirty × 10

Push rod fixing part -60 × fifty × 10

Push rod fixing part two Φ thirty × 60 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Thin walled rubber tube light processing clamping fixture | Size: 150 × one hundred and fifty × 120

Clamp specific Φ one hundred and forty-seven × 117

Rubber hose Φ eighty × 60

Nut M8 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| External clamping device for hoop | Overall size 160 × one hundred and eighty × 45

Size: φ one hundred × 160

Overall size 160 × one hundred and eighty × 40

Clamp specific 110 × sixty × 40

Clamp specific II 50 × one hundred and ten × 40

Clamp specific II 50 × one hundred and ten × 40

Connecting rod 20 × ninety × 30

Clamping handle 40 × ninety × 80 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Spiral clamping structure with fine-tuning device | Overall size 150 × three hundred × 128

Size: 200 × one hundred × 120

Fixture base plate 150 × two hundred × 10

Fine tune the fixed block 150 × sixty × 90

sleeve Φ forty × 110

Axis One Φ twenty × 90 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| External swinging clamping device | Overall size 200 × one hundred × 125

Size: 160 × one hundred × 120

Fixture base plate 100 × two hundred × 100

Upper pressure plate 193 × one hundred × 20

Pin shaft Φ eight × 70

Side positioning block 40 × forty × 20

Connecting plate 60 × sixty × 30 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Spiral clamping structure inside the box frame | Overall size 200 × two hundred and forty-five × 75

Fixture base plate 200 × two hundred × 15

Pad 100 × thirty × 10

Side positioning block 45 × fifty × 10

Connecting plate 80 × thirty × 20

Locking handle Φ fifty × 210 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Internal tensioning and clamping device | Overall size Φ one hundred and seventy-two × 170

Size: 150 × one hundred and fifty × 160

Round sleeve Φ eighty × 30

Rotating body Φ one hundred and seventy × 110

Internal circular sleeve Φ ninety × 30

Inner sleeve Φ fifty × 10

axis Φ twenty × 130 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Adjustable cam clamping device | Overall size 271 × one hundred and eight × 145

Size: 100 × one hundred and twenty × 160

Base 270 × ninety × 30

V-shaped block positioning plate -50 × fifty × 10

V-block fixing plate 80 × eighty × 30

V-block 20 × twenty × 70

V-shaped block positioning plate II 50 × fifty × 10 workpieces Φ ten × 80 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Pneumatic clamping milling machine fixture | Overall size 250 × two hundred × 212

Fixture base 250 × one hundred and twenty × 25

V-block 40 × forty × 30

End face top block 50 × forty × 40

Radial clamping block 50 × forty × 80

Top rod fixing parts Φ ten × 50 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Gap fit cylindrical core shaft fixture | Size: 290 × ninety × 90

Mandrel body Φ eighty × 290

Open gasket Φ seventy × 20

workpiece Φ ninety × 160

Nut processing part M30 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Spring core shaft fixture | Overall size Φ ninety × 160

Size: 312 × ninety × 90

Mandrel body Φ eighty × 310

Spring tube clamp Φ eighty × 140

Conical sleeve Φ seventy × 80

workpiece Φ ninety × 160 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Structure of push type spring chuck | Overall size Φ seventy-five × 160 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| The structure of the floating joint | Size: φ sixty × 160 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Elbow type clamping device | Size: 180 × one hundred × 120 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Cover type drilling machine fixture | Overall size 287 × one hundred and seventeen × 73

Size: 280 × one hundred and ten × 80

Mandrel body Φ eighty × 290

Open gasket Φ seventy × 20

workpiece Φ ninety × 160

Nut machining part M30

Fixture table 250 × one hundred and ten × 30

Drilling template 280 × one hundred and ten × 10 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Box drilling die | Overall size 106 × one hundred and eight × 143

Size: 140 × one hundred and ten × 120

Left side panel 110 × ninety × 10

Left side panel 110 × ninety × 10

Front panel 80 × eighty × 10

Rear panel 80 × seventy × 10 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Left and right bracket drilling fixtures | Overall size 160 × two hundred and five × 187

Size: 200 × one hundred and fifty × 120

Fixture seat 150 × one hundred × 90

Cushion block 50 × ninety × 30

Adjustable connecting plate 180 × fifty × 10

Connecting plate 40 × one hundred and ten × 10

Workpiece 120 × eighty × 10

Shim Φ thirty × 7

Gear 8 × two Φ twenty × 140 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Double arm crank drilling combination fixture | Overall size 298 × two hundred and twenty × 151

Fixture motherboard 220 × one hundred and fifty × 60

Positioning square 60 × sixty × 60

Limit block 90 × twenty × 10

Drill sleeve plate 90 × thirty × 10

Drilling sleeve Φ ten × 10

Screw M8 × 80

Screw slider 20 × twenty × 10 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

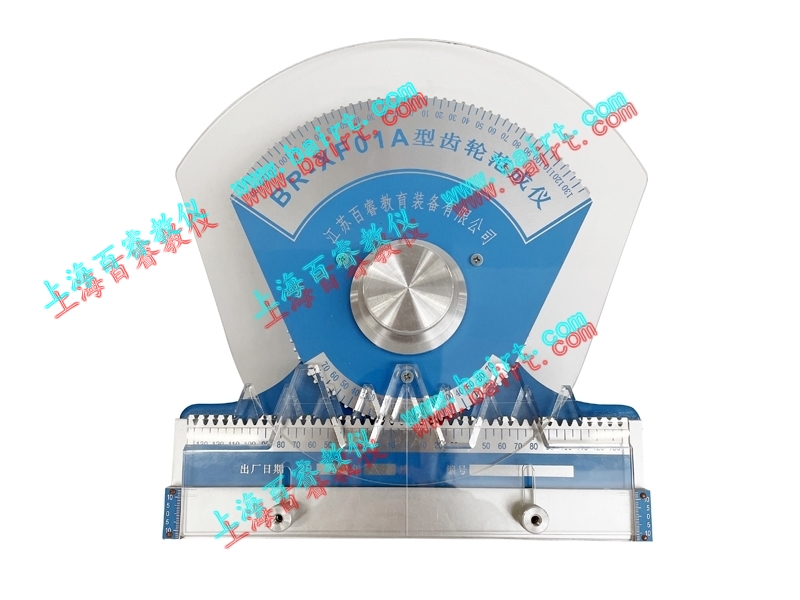

| Indexing drilling machine fixture | Overall size 160 × two hundred × 220

Clamp specific one 200 × one hundred and sixty × 20

Clamp specific II 160 × one hundred and sixty × 20

Round nut M16

Dingpin sleeve Φ forty × 60

Targeted sales Φ ten × 80

Handle Φ ten × 70

Drill template 100 × ninety × 20

Drilling sleeve Φ thirty × 30 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Rotary drilling die | Overall size 160 × two hundred × 220

Size: 180 × one hundred and forty × 140

Clamp specific one 200 × one hundred and sixty × 20

Clamp specific II 160 × one hundred and sixty × 20

Round nut M16

Dingpin sleeve Φ forty × 60

Targeted sales Φ ten × 80

Handle Φ ten × 70

Drill template 100 × ninety × 20 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Flipping drill die | Overall size 116 × one hundred and twenty-five × 98

Size: 160 × two hundred × 150

Clip specific 125 × ninety × 20

Clamp specific two 125 × eighty × 20

Positioning pin Φ six × 40

Positioning pin Φ six × 50

Drilling template 150 × forty × 10 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Manual sliding column drilling die | Overall size 130 × one hundred and forty-five × 170

Size: 180 × one hundred and ninety × 210

Base 170 × one hundred and thirty × 30

Clamp specific 100 × one hundred and thirty × 50

Fixed block 30 × forty × 20

Drill sleeve assembly 130 × one hundred and seventy × 20

Lifting guide rod Φ thirty × 120

Guide rod Φ thirty × 120 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Drilling fixture with indexing device | Overall size 141 × two hundred and thirty-six × 140

Size: 210 × one hundred and eighty × 130

Clamp specific Φ one hundred and forty × 60

Hinged drilling template 130 × fifty × 30 handles Φ thirty × 60

Drilling template 60 × twenty × 10

Drilling sleeve Φ twenty × 20

Compression screw Φ ten × 20

Workpiece 40 × eighty × 110 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Hinged drilling machine fixture | Overall size 140 × two hundred and twenty-eight × 212

Size: 250 × ninety × 130

Base 140 × one hundred and fifty-five × 150

Hinged frame 120 × forty × 40

Drilling sleeve Φ twenty × 50

Open gasket Φ fifty × 8

Hinge rod 160 × forty × 20

workpiece Φ one hundred × 80 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Hanging drilling template drilling machine fixture | Overall size 170 × one hundred and thirty-nine × 183.5

Size: 230 × one hundred and sixty × 160

Base 170 × one hundred and thirty × 30

Clamp specific 1130 × one hundred and thirty × 10

Clamp specific 2130 × one hundred and thirty × 10

Guide rod Φ ten × 140

Gear shaft 2 Φ ten × 50 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Multi sided flipping drilling machine fixture | Overall size 168 × one hundred and forty-five point five × 147

Size: 140 × one hundred and forty × 170

Shell 160 × one hundred and forty × 100

Copper sheet Φ one hundred × 7

Base 160 × one hundred and forty × 40 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Fork group drilling machine fixture | Overall size 150 × one hundred and fifty × 162

Size: 200 × one hundred and thirty × 190

Bottom plate 150 × one hundred and fifty × 20

Positioning sleeve Φ ten × 10

Cover plate 110 × seventy × 10

Fixed axis Φ thirty × 92

Clamp specific 150 × one hundred and twenty × 20

Connecting rod 150 × twenty × 10 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Diagonal drilling machine fixture | Overall size 167 × one hundred and sixty-six × 170

Size: 160 × one hundred and fifty × 160

Clamp specific 160 × one hundred and ten × 160

Locking rod Φ twenty × 130

Lock nut M16 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Rocker arm locking hole drilling die | Overall size 158 × two hundred and fifty-five × 132

Size: 200 × one hundred and twenty × 120

Drilling template 70 × twenty × 10

Base 250 × ninety × 20

Clip specific 190 × ninety × 90

Hanging board 80 × forty × 9

Wedge block Φ forty × 30 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Universal adjustable drilling machine fixture | Overall size: 180 × two hundred and fifty-five × 132

chassis Φ one hundred and eighty × 25

Clip specific one Φ ninety × 140

Clamp specific two 200 × one hundred and thirty × 20

Positioning sleeve Φ one hundred and ten × 40

Pressure plate fixing plate 80 × thirty-five × 30 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Short axis drilling group drilling machine fixture | Size: 200 × one hundred and sixty × 100 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Steel sleeve drilling die | Size: φ one hundred × 120 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Detachable drilling template | Size: 260 × one hundred and twenty × 110 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Fixed drilling jig | Size: 190 × one hundred and twenty × 150 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Universal rotary drilling machine fixture | Size: 330 × one hundred and thirty × 170 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Bracket oblique hole indexing drilling die | Size: 200 × one hundred and sixty × 100 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Suspended drilling template | Size: 220 × one hundred and seventy × 140 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Milling Machine Fixture for Milling Tee Slots | Overall size 188 × one hundred and thirteen × 185

Size: 200 × one hundred and sixty × 115

Clamp specific 150 × one hundred and eighty × 110

Sleeve 50 × ninety × 30

Mandrel Φ sixty × 190

Knife block 20 × thirty × 40 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Multi piece linkage clamping milling machine fixture | Overall size 290 × one hundred and sixteen × 95

Size: 240 × one hundred and twenty × 80

Clamp specific one 290 × one hundred and ten × 80

Up and down adjustment plate 200 × thirty × 10

Positioning key 10 × ten × 20

Activity V-block 40 × twenty × 10

Activity V-block 240 × twenty × 10 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Model milling machine fixture | Overall size 250 × one hundred and seventy-two × 145

Size: 200 × one hundred and seventy × 190

Prototype fixture chassis 250 × one hundred and sixty × 25

Model fixing rod Φ fifty × 120

Model nut M20 machining by turning

Model cushion plate Φ sixty × 6

Model piece 160 × one hundred and twenty × 10

Simulated milling cutter Φ thirty × 120 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Eccentric clamping milling machine fixture | Overall size 312 × one hundred × 105

Size 230 × one hundred and forty × 180

Base 260 × one hundred × 20

Fixed V-shaped block 40 × seventy × 80

Knife block 40 × thirty × 10

Activity V-block 40 × fifty × 80

Clamp specific 30 × seventy × 100

Handle Φ ten × 100 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Double circular axis milling keyway fixture | Overall size 108 × two hundred and eight × 105

Size: 180 × one hundred and twenty × 120

Base 200 × one hundred × 20

Washers Φ twenty × 20

Positioning key 20 × ten × 10

Cutting plate 90 × twenty × 4

Clamp specific 100 × ninety × 30 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Circular workpiece milling machine fixture | Overall size 131 × two hundred and fifty × 90

Size: 220 × one hundred and twenty × 100

Base 210 × one hundred and thirty × 90

Shim Φ thirty × 9

Eye bolt M8

Top tier Φ twenty × 40

Top rod Φ ten × 70

Top seat 40 × seventy × 90 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Fixture for milling bearing shells | Overall size 123 × one hundred and ninety-one × 155

Size: 160 × one hundred and fifty × 120

Base 180 × one hundred and twenty × 100

Top pin Φ eight × 60

Top pin handle Φ ten × 10

Top pin cylinder Φ ten × 40 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Fork keyway milling machine fixture | Overall size 140 × one hundred and eighty × 85

Size: 160 × one hundred and twenty × 140

Base 140 × one hundred and eighty × 20

Pressing plate 30 × forty × 50

Workpiece 20 × fifty × 100

Centering axis Φ forty × 40

Positioning key 20 × ten × 10 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Jig for group milling machine with fork mouth | Overall size 200 × two hundred and sixty × 90.5

Size: 210 × one hundred and seventy × 210

Base 200 × two hundred and sixty × 20

Backing plate 200 × two hundred × 20

Positioning rod Φ sixteen × 30

Clamp specific Φ two hundred × 20 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Wedge linkage clamping milling machine fixture | Overall size 120 × two hundred and sixty × 125

Size: 240 × one hundred and fifty × 270

Workpiece 30 × thirty-five × 120

optical axis Φ twelve × 120

Clamp specific 120 × two hundred and sixty × 20

Clamp specific II 50 × one hundred and sixty × 20

Clamp specific three 50 × one hundred and twenty × 20

Clamp specific four 120 × one hundred and thirty × 20 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Milling machine fixture with auxiliary support | Overall size 110 × two hundred and sixty × 130

Size: 210 × one hundred and fifty × 160

Base 110 × two hundred and sixty × 20

Positioning block 30 × sixty × 20

Positioning block II 30 × thirty × 10

Block 10 × forty × 8

Support bracket 40 × sixty × 80 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Indexing milling machine fixture | Overall size 215 × two hundred and fifty × 184

Size: 300 × two hundred × 120

G workpiece Φ seventy × 50

Fixture table Φ one hundred and seventy × 40

Screw fixing plate 100 × twenty × 10

Handle Φ ten × 110

Pressing plate 50 × twenty × 10

Screw M10 × 80

Compression nut Φ fifty × 10

Connecting shaft M8 handle sleeve × 0 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Linkage clamping milling machine fixture | Size: 270 × one hundred and twenty × 140

Clamp specific 260 × one hundred and forty × 25

V-block 120 × thirty × 40

V-block II 120 × thirty × 30

Pressing block 120 × thirty × 10 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Keyway milling machine fixture | Overall size 260 × one hundred and forty × 100

Clamp specific 260 × one hundred and forty × 25

V-block 120 × thirty × 40

V-block II 120 × thirty × 30

Pressing block 120 × thirty × 10

Pole foot Φ twenty × 40

Screw One Φ ten × 60 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Continuous clamping adjustable milling machine fixture | Size: 180 × one hundred and twenty × 150 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Centrifugal force lathe fixture | Overall size Φ one hundred and forty-eight × 291

Size: φ one hundred and sixty × 280

Handle 100 × thirty × 20

Protective cover Φ one hundred and forty × 80

Elastic shaft sleeve Φ twenty × 40

Flange plate Φ eighty × 40

Centrifuge workpiece 50 × fifty × 20 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Group turning tool fixture | Overall size 175 × one hundred and seventy-five × 138

Transition disc Φ one hundred and seventy-four × 58

Clamp specific Φ one hundred and seventy × 20

Balance block 100 × thirty × 20

Adjustable fixture table 150 × sixty × 20

Workpiece pressing block 40 × twenty × 10

T-shaped slider 20 × twenty × 10

Cylindrical pin Φ six × 35 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Angle iron lathe fixture | Overall size Φ two hundred and sixty × 295

Size: 160 × one hundred and twenty × 180

Clip specific one Φ two hundred and sixty × 20

Clamp specific II 150 × one hundred and sixty × 20

Swinging V-block 40 × sixty × 20

Positioning pin Φ twenty × 60

Pole foot Φ twenty × 50

Workpiece 80 × eighty-nine × 90 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Pipe joint group lathe fixture | Overall size Φ one hundred and sixty × 301

Size: φ one hundred and sixty × 250

Transition disc Φ one hundred and sixty × 180

Centering axis Φ ten × 80

Sliding nut Φ twenty × 30

Tightening plate 30 × thirty × 10

Fixture table Φ one hundred and sixty × 110

Snap ring Φ ten × 10 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Group lathe fixtures for disc and sleeve parts | Overall size Φ one hundred and eighty-nine × 259

Size: φ one hundred and eighty × 210

Workpiece 70 × seventy × 70

Positioning axis 1 Φ fifty × 50

Positioning axis 2 Φ seventy × 140

Slide 10 × thirty × 10 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Fork mouth group lathe fixture | Overall size Φ one hundred and eighty-five × 96

Size: φ one hundred and eighty × 80

Workpiece 70 × eighty × 20

Mirror oriented workpiece 70 × eighty × 20

Clamp specific Φ one hundred and eighty × 20

Cushion block Φ twenty × 18

Positioning block 50 × fifty × 10 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Lathe fixture with indexing device | Overall size Φ one hundred and eighty × 151

Size: φ one hundred and eighty × 140

Positioning column Φ eight × 90

Round head Φ twenty × 20

Arc bar 30 × ninety × 10

Clamp specific Φ one hundred and fifty × 50

Pressing block 20 × thirty × 40 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Crankshaft neck lathe fixture | Overall size Φ one hundred and seventy-five × 185

Size: φ one hundred and sixty × 150

Crankshaft base Φ one hundred and seventy × 20

Fixed part of crankshaft neck Φ one hundred and ten × 80

Crankshaft sleeve Φ fifty × 50

Side top plate 70 × twenty × 10

Workpiece - crankshaft neck 140 × seventy × 50 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Circular spiral clamping lathe fixture | Overall size Φ two hundred and fifty × 100

Size: φ two hundred × 110

base Φ two hundred and fifty × 20

Workpiece 100 × forty × 20

Spiral clamping assembly 30 × forty × 50

Arc bar 170 × sixty × 10

Spiral clamping mechanism Φ ten × 90

Forcing rod Φ six × 40 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Special vehicle eccentric lathe fixture | Overall size Φ two hundred × 66

Size: φ one hundred and sixty × 160

base Φ two hundred × 30

Block 130 × thirty × 20

Block 230 × thirty × 20

motherboard Φ two hundred × 40 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Pump body hole lathe fixture | Size: 190 × one hundred and fifty × 120 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Four types of connections between lathe fixtures and machine tool spindles | Size: 200 × two hundred and fifty × 150 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Lathe fixture for machining holes on opening and closing nuts | Size: φ one hundred and eighty × 150 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Fixture for indexing lathe with outer circular and square groove of cross shaft | Size: φ one hundred and sixty × 120 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Thin walled sleeve elastic lathe fixture | Size: φ ninety × 160 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Shell lathe fixture | Size: φ one hundred and sixty × 140 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Fixture for return water cover indexing lathe | Size: 180 × one hundred and fifty × 120 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Fixture for precision boring of large and small holes in connecting rods | Overall size 255 × one hundred and eighty × 100

Chassis 255 × one hundred and eighty × 20

Component One 100 × fifty × 40

V-block 60 × thirty × 10

Cushion block 30 × thirty × 10

Cushion block II 30 × thirty × 10

Block cylinder 40 × forty × 40

Block seat 20 × twenty × 40 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Box boring machine fixture | Overall size 270 × two hundred and twenty-eight × 128

Fixture base plate 228 × one hundred and sixty-five × 20

Pressing plate support bolt Φ ten × 80

Fixing pin for pressure plate Φ ten × 110

Pressing plate 50 × thirty × 10

Positioning block 40 × twenty × 10

Stall 80 × ten × 8 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Front and rear double support boring machine fixture | Overall size 150 × two hundred and ninety-seven × 157

Side seat 113 × one hundred and seventeen × 27

Block 160 × sixty × 60

Block 250 × seventy × 10

Stop 320 × sixty × 6

Bottom plate 240 × one hundred and forty × 20

Mirror facing side seat 110 × one hundred and ten × 20 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Oblique wedge-Slider type hollow fixture | Overall size Φ one hundred and seventy-two × 175

Specific wedge clamp Φ one hundred and seventy × 100

Oblique wedge Φ thirty × 110

Wedge block 80 × sixty × 20

Slide 10 × ten × 8 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Double support boring machine fixture (with boring cutter) | Size: 250 × one hundred and ninety × one hundred and forty | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

| Boring Machine Fixture for Boring Lathe Tailstock Holes | Size: 220 × one hundred and sixty × 130 | Premium fixtures, made of aluminum alloy, equipped with 3D virtual simulation courses |

Return to homepage

Return to homepage Immediately call for consultation

Immediately call for consultation About Us

About Us Immediately consult online

Immediately consult online